|

The

strength of the given invention consists first of all that the RPEY can be made

in metal construction of a standard three-phase asynchronous electric motor by a

rotor with squirrel cage only by replacement of stator windings.

All

metal construction of asynchronous electric motor and all technology of its

assembly remain former. There is no need to retrain the personnel and to equip

manufacture with what or new machine tools and equipment.

The

RPEY made in metal construction of traditional asynchronous electric motor keep

all positive properties of the asynchronous electric motor, but thus there are

new unique properties:

1 The RPEY are

adjusted by smooth regulation of a voltage at constant frequency of a current.

Result:

Millions of consumers will receive accessibility for smaller price, reliable and

convenient in operation energy saving electric motors. Externally, RPEY can not

be distinguished from traditional asynchronous engines and it is easy to build

in to the existing process equipment. The high quality of energy on an input of

the electric motor is provided with auto transformers, simple, reliable,

accessible in price, and can be hand-operated or with a remote control. Thus

highly skilled attendants are not required. The operational charges do not

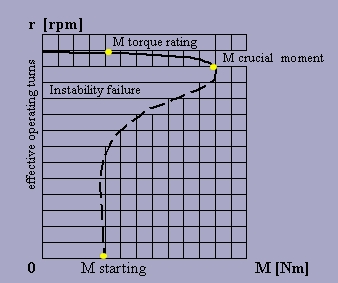

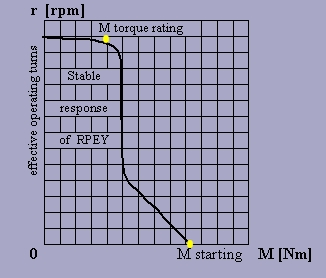

grow. 2. Mechanical

characteristic is steady and starting moment maximal and is 2 or 3 times more

than at the asynchronous electric motor.

Result:

Even to units with heavy start-up, apply RPEY without excess of the established

capacity, and consequently the electric motor works in the field of high

EFFICIENCY. It allows RPEY to be used in especially heavy cases of operation -

in mode of operations with a blocked rotor, for example, in a drive of rolling

mills or drive of drilling rigs.

3. At non-nominal loading the power

EFFICIENCY of RPEY is reduced insignificantly, as opposed to asynchronous

electric motors.

Result:

Even in a non-controllable drive at frequently varying loading, RPEY work more

economically than asynchronous by 2 -3 times. 4.

At significant fluctuations of voltage, including fall in some times, not

"overturns", as the asynchronous motor and steadily continues to work with

smaller capacity, but with high EFFICIENCY.

Result:

Safety in operation and high average EFFICIENCY on a long interval of time,

including work with alternating loadings, often start-up, stops, reversal,

idling and with small loadings. 5.

Repetition factor of starting currents is lowered with 7 up to 3.5. Result:

Automatically, without special devices the smooth start-up without impacts on

the connected machine is provided, the overheating is reduced during often

start-up and stops, the between-repairs resource raises. 6.

The critical overload of the engine is accompanied by smooth decrease of

revolutions of the shaft - critical moment and sharp stop is absent. Result:

The safety in operation of the engine and connected machine is increased; the

allowable number of start-up and stops during the given time and in special

modes is increased. 7.

The overall dimensions and weight are reduced on 25 % - 100 %, at preservation

of landing places of the asynchronous engine of similar capacity and

purpose. Result:

In standard dimensions of the asynchronous electric motor it is possible to

increase capacity by 25 %, and in a case of submersible electric motors it was

possible to raise capacity on 100 % (in 2 times).

The

result is magnificent.

|

There

are, electric motors, which were developed more than hundred years was lead up

by the best research institutes and firms all over the world, can have on

hundreds kg less weight at the same useful capacity, besides that, there are new

unique properties. It has become possible due to the invention essentially of

new concept of project of electric motors of an alternating current.

Results

of tests modernized on the circuit RPEY of the serial asynchronous electric

motor ю4-400у, capacity of 500 kW (680 HP). In the factory protocols RPEY is

written down as ою-400у

|

The

name of parameter

|

ю4-400у

|

ою-400у

|

ю4-400сл

|

|

1. Rated power,

kW.

|

500

|

646

|

618

|

|

2. Rated voltage,

V.

|

6000

|

6000

|

6000

|

|

3. Rated current

of a phase, ю.

|

58

|

72,5

|

71,5

|

|

4. Sliding, %.

|

1,3

|

1,14

|

1,3

|

|

5. Weight of

the electric motor,

kg.

|

2070

|

2070

|

2290

|

|

6. Effectiveness

ratio of EFFICIENCY,

%.

|

94,7

|

95,6

|

94,5

|

|

7. Factor of

capacity Cos , %. , %.

|

88

|

89,6

|

88

|

|

8. Moment of

inertia of a rotor,

kg m2

|

11

|

11

|

13

|

|

9. Time of transient,

sec.

|

0,538

|

0,345

|

0,4

|

|

10. Allowable

deviations of a

voltage from nominal,

%.

|

+10%-5%

|

+20%-80%

|

+10%-5%

|

|

11. Starting

moment, Йg m

|

322,6

|

503

|

479

|

|

12. Total losses

of the engine, kW.

|

28

|

29

|

36

|

|

After

modernization of the serial asynchronous electric motor ю4-400у-с3 under the

circuit RPEY, the useful capacity has increased on 146 kW (198.56 HP). Thus the

heating has decreased, and it means that is possible still to increase

capacity.

In

the same dimensions, but instead of 500 kW (680 HP) have received 646 kW (878.56

HP). The following on capacity the serial asynchronous electric motor

ю4-400сл-4сг has under passport 630 of kW (856,8 HP). Really develops only 618

kW (840.48 HP) and weight on 220 kg more.

Hence

economy of materials makes 220

kg, and stamped from dear electro-technical steel of

stator plates and bus-bar armature copper, and it is a nominal mode of

operations.

Besides

at the modernized asynchronous electric motor the frequency of rotation of the

shaft is adjusted simple by the multi-winding three-phase transformer. This new

property is not inherent in the asynchronous electric

motor.

But

the main difference from the standard asynchronous electric motor is energy

saving of property of RPEY. The traditional asynchronous electric motor has good

power parameters only in one point - point of nominal mode of operations.

The

energy saving RPEY motor has high power parameters in a wide range of change of

loading and voltage. The executed projects of RPEY have captured power line from

0.25 kW (0.34 HP) up to 2000 kW (2720 HP).

The

novelty of the technical decisions used by development of RPEY is confirmed by

the patents of Russia,

USA, Canada, Austria, Germany, France, Great

Britain,

and

Italy.

In

the conclusion, we shall note: the asynchronous electric motors can be replaced

on RPEY with huge economic benefit. We plan to create the first in the world

factory to manufacture the energy saving RPEY electric motors.

We

invite to this perspective project investors and all interested physical

and legal persons. |

|

, %.

, %.